Trade Counter Open Monday to Friday, 8.30am-5pm

Hypertherm Plasma Cutters

Hypertherm Plasma Cutters: Industry-Leading Technology for Superior Metal Cutting

When it comes to precision, reliability, and performance in metal cutting, few brands are as respected as Hypertherm plasma cutters.

Known around the world for their innovation and engineering excellence, Hypertherm has been at the forefront of plasma cutting technology for decades, and Xtreme Plasma is proud to be a supplier of them.

Designed for professionals in fabrication, automotive, shipbuilding, construction, and more, these machines deliver power, accuracy, and efficiency across a wide range of cutting applications.

Unmatched Cutting Precision

One of the standout features of Hypertherm plasma cutters is their ability to produce highly accurate, clean cuts on various conductive metals.

Whether you're working with mild steel, stainless steel, or aluminium, these machines deliver minimal dross and virtually no warping, even on thick materials.

The result is a smoother cut edge that requires little to no post-processing.

Advanced arc stability, high-definition cutting, and fine feature capabilities make Hypertherm the preferred choice for precision work.

These machines can handle both intricate patterns and industrial-grade jobs with ease, offering unmatched flexibility in metal fabrication.

Smart Technology That Boosts Performance

Hypertherm plasma cutters are equipped with intelligent technologies that enhance efficiency and user experience.

Many models feature auto gas control, which adjusts the gas flow based on material type and thickness.

This results in optimised performance and reduced waste.

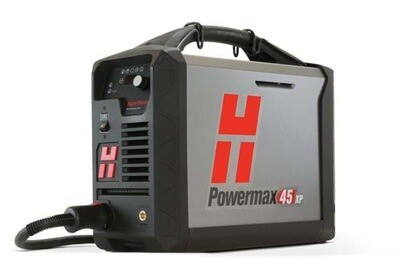

The Powermax series, such as the Hypertherm Powermax 45, includes features such as Smart Sense technology.

This monitors gas pressure and automatically adjusts it for consistent performance.

The addition of consumable detection helps extend part life and avoid mistakes, making Hypertherm systems ideal for both experienced fabricators and those just learning plasma cutting techniques.

Built for Rugged Environments

Durability is a key benefit of Hypertherm plasma cutters.

Built with industrial-grade components and housed in robust casings, these machines are designed to withstand challenging conditions, whether in a busy workshop, a dusty construction site, or a remote repair location.

Internal components are well protected, and advanced cooling systems help prevent overheating during prolonged use.

Many models are also designed to be easily portable, with ergonomic handles and lightweight construction that make them practical for mobile welding and cutting services.

CNC Compatibility for High-Volume Production

For workshops that require precision and repeatability in high-volume settings, Hypertherm plasma cutters offer full CNC plasma table compatibility.

Their systems are widely used in automated cutting tables and robotic systems, where exact results are essential.

With reliable communication interfaces and finely tuned motion control, Hypertherm’s CNC-ready machines help manufacturers streamline their operations, reduce errors, and maintain consistent quality across production batches.

This capability makes them a top choice for industries like automotive manufacturing, aerospace, and metal fabrication plants.

Low Operating Costs and Long Consumable Life

A major selling point of Hypertherm plasma cutters is their cost-efficiency.

Despite their premium status, these machines are designed to minimise operating expenses.

Consumables in Hypertherm systems last significantly longer than many competing brands due to innovative nozzle and electrode design.

In addition, efficient power use and minimal downtime translate into real savings over time.

Operators find they can complete more cuts with fewer interruptions and less maintenance, improving overall productivity.

User-Friendly Controls and Interfaces

Despite their advanced capabilities, Hypertherm plasma cutters are surprisingly easy to use.

Simple control panels, digital displays, and intuitive adjustment settings ensure that users can begin cutting with minimal training.

Hand-held torch models are ergonomically designed, with comfort grips and responsive triggers to reduce fatigue during long cutting sessions.

For those using automated systems, Hypertherm’s software and interface tools are streamlined for easy integration and programming.

A Model for Every Cutting Need

Hypertherm offers a range of machines to suit various needs and budgets.

From compact systems like the Powermax30 AIR, which includes a built-in air compressor, to powerful models like the Powermax125 capable of cutting over 50mm thick steel, there’s a machine for every user.

Whether you're cutting thin sheet metal for signage or slicing through heavy structural beams, Hypertherm plasma cutters provide the precision and performance required to do the job right.

Strong Global Support and Warranty

Another advantage of choosing Hypertherm plasma cutters is the strong support network that comes with them.

The company offers outstanding technical assistance, comprehensive user guides, training resources, and a global distribution network.

This ensures that users receive the help they need wherever they are in the world.

The Cutting Standard You Can Rely On

For anyone seeking high-performance, professional-grade cutting equipment, Hypertherm plasma cutters are a top-tier option.

They combine innovation, durability, and efficiency in a way few other brands can match.

With smart features, low operating costs, and precision engineering, Hypertherm has set the standard in the plasma cutting industry.

Whether you’re running a fabrication business, working on custom metal projects, or managing an industrial production line, Hypertherm plasma cutters provide the tools you need to cut faster, cleaner, and with greater confidence.

For more information on plasma cutters, or help with any and all of your plasma cutting needs, get in contact with us here at Xtreme Plasma.

Refine by

Display prices in:GBP