Trade Counter Open Monday to Friday, 8.30am-5pm

What is Plasma Cutting and How Does it Work?

Plasma cutting is a modern technique used to cut through various metals with remarkable precision.

It has become a popular method in industries and workshops around the world.

But exactly what is plasma cutting, and how does it work?

In this article, we’ll explore the basic principles behind plasma cutting and why it’s considered such a valuable tool for cutting metal.

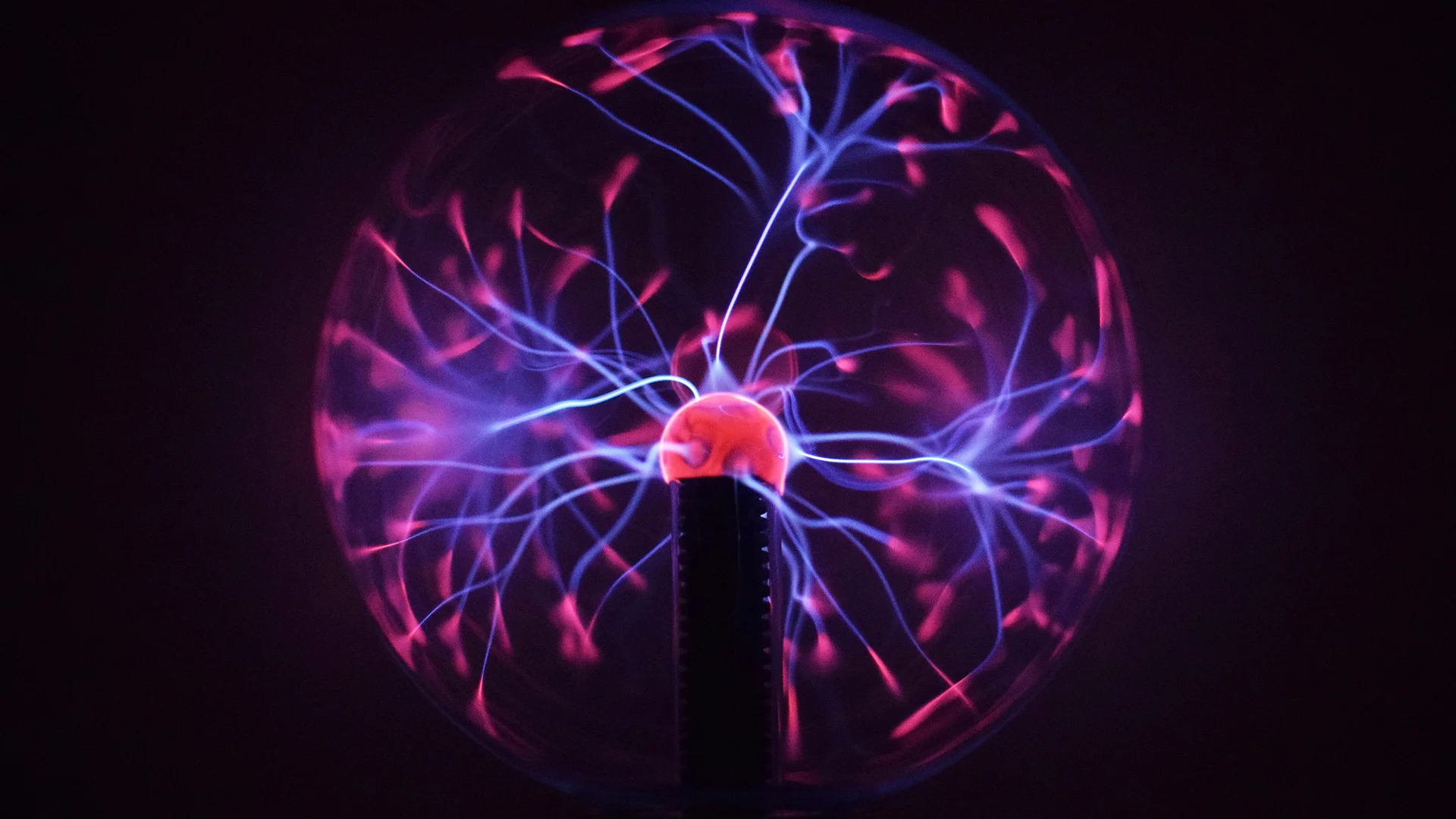

What is Plasma?

Plasma is often called the fourth state of matter, alongside solids, liquids, and gases.

It occurs when a gas is energised to the point that some of its atoms break apart into freely moving electrons and ions.

This mixture of charged particles makes plasma very different from ordinary gases.

It becomes electrically conductive and responds strongly to magnetic and electric fields.

Plasma is more common in the universe than we might think.

Stars, including our Sun, are made up of plasma.

On Earth, we see plasma in natural phenomena such as lightning and the northern lights.

Man-made examples include fluorescent lights, plasma televisions, and plasma torches used in cutting and welding processes.

In industrial settings, plasma is created by heating a gas, such as air, nitrogen, or argon, to very high temperatures.

This ionisation process turns the gas into plasma, allowing it to conduct electricity and generate extreme heat.

The unique properties of plasma make it highly valuable for applications where controlled energy and heat are required.

In plasma cutting, the focused jet of plasma is so hot that it melts metal with precision.

Its ability to handle conductive materials cleanly and quickly is what makes plasma an ideal tool in manufacturing and fabrication industries.

What is Plasma Cutting?

Plasma cutting is a thermal cutting process used to slice through electrically conductive metals with precision and speed.

It works by using a plasma torch to create an extremely hot, high-velocity jet of ionised gas, or plasma.

This plasma stream reaches temperatures of up to 30,000°C, which is hot enough to melt metal almost instantly.

As the metal melts, the force of the gas blows the molten material away, leaving a clean and narrow cut.

The technique is widely used in industries such as automotive repair, shipbuilding, metal fabrication, construction, and aerospace.

Plasma cutting is favoured over traditional cutting methods because of its accuracy, speed, and the minimal need for post-cut finishing.

Unlike mechanical cutting methods, plasma cutting does not require physical contact with the material, reducing wear on the equipment.

Its ability to produce clean, precise cuts with minimal heat-affected zones makes it a highly efficient and cost-effective choice for metalworking.

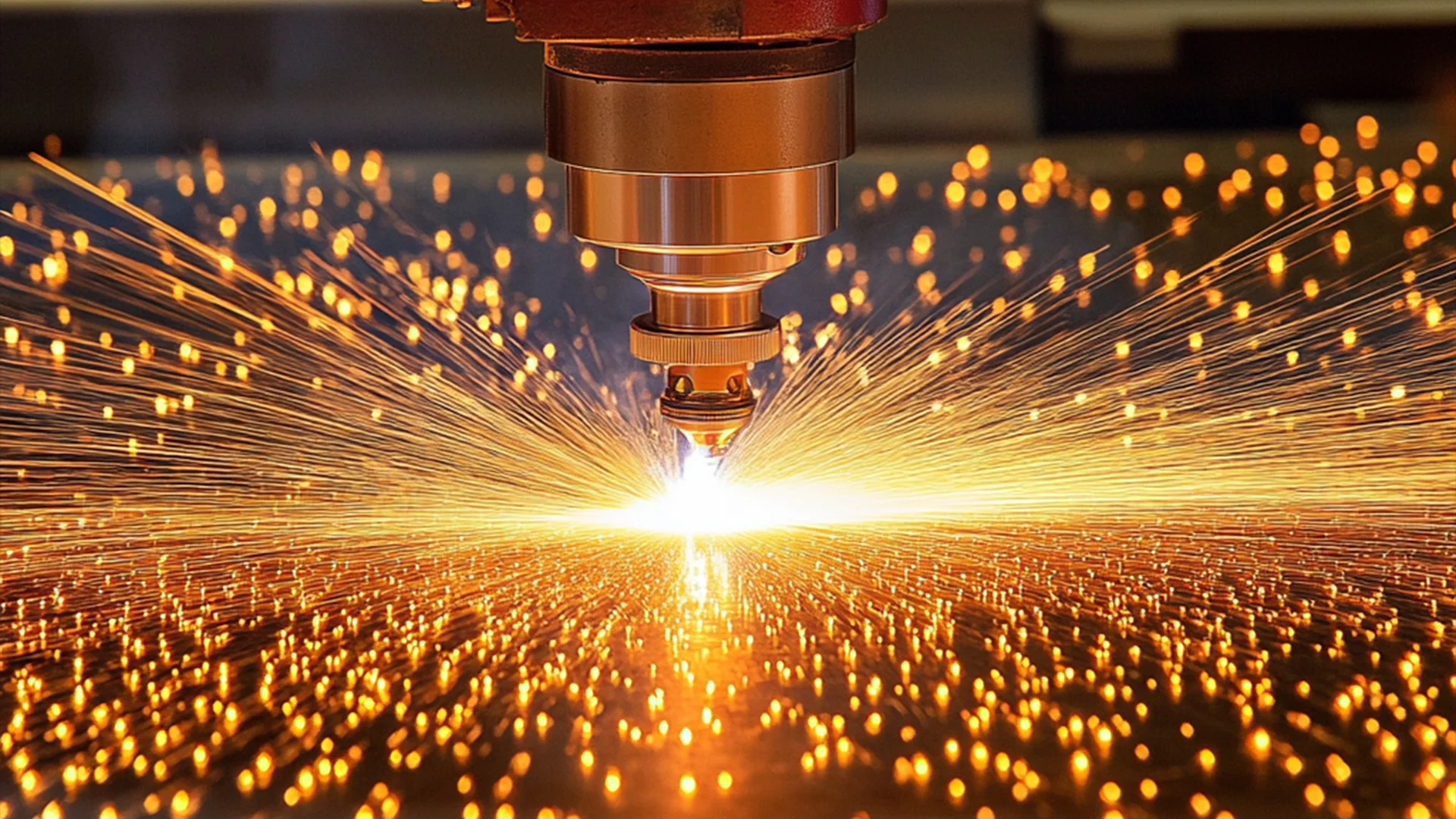

How Does Plasma Cutting Work?

Plasma cutting works by creating an electrical channel of superheated, electrically ionised gas, known as plasma, between the cutting tool and the metal workpiece.

This plasma stream is hot enough to melt metal and strong enough to blow the molten material away, creating a clean, precise cut.

Key Components of a Plasma Cutter

A typical plasma cutting system consists of a power supply, a plasma torch, a gas supply, and an electrode.

The power supply delivers energy to maintain the plasma arc.

The torch holds the electrode and nozzle, guiding the plasma onto the material.

Compressed gas, often air, nitrogen, or argon, passes through the torch and is ionised to form plasma.

The Cutting Process

Ignition

When the machine is switched on, a high-frequency spark ionises the gas, creating plasma.

An arc forms between the electrode and the metal surface.

Plasma Jet Creation

The ionised gas reaches extreme temperatures of up to 30,000°C.

This forms a concentrated plasma jet that melts the metal along the cutting line.

Metal Removal

The velocity of the gas stream blows the molten metal away from the cut, leaving a smooth and narrow kerf (cut line).

The cutting speed and gas flow can be adjusted depending on the material thickness.

Types of Plasma Cutting

- Handheld Plasma Cutters: These are portable and ideal for on-site work or smaller tasks. They can typically cut materials up to 25-38 mm thick.

- CNC Plasma Cutters: CNC plasma cutters are used for complex or large-scale projects. They offer greater accuracy and can cut materials up to 150 mm thick.

What Can You Cut with Plasma Cutting?

Plasma cutting is suitable for a variety of electrically conductive metals, including:

Mild Steel

Mild steel is one of the most common materials cut with plasma.

It is widely used in construction, automotive manufacturing, and general metal fabrication.

Plasma cutting offers fast, clean cuts through mild steel sheets and plates of varying thicknesses.

Stainless Steel

Stainless steel is valued for its corrosion resistance and strength.

It is often used in food processing, medical equipment, and architectural projects.

Plasma cutting provides precise cuts through stainless steel without compromising its properties, making it an ideal method for this material.

Aluminium

Aluminium is a lightweight, versatile metal frequently used in aerospace, transport, and packaging industries.

Plasma cutting is particularly effective on aluminium sheets and plates, offering high cutting speeds and smooth edges with minimal distortion.

Copper and Brass

Copper and brass are commonly used for electrical components, plumbing, and decorative purposes.

Both metals conduct electricity well, which makes them suitable for plasma cutting.

The process provides accurate cuts with minimal heat-affected zones, which is important when working with these materials.

Thickness Range

The thickness of materials that plasma cutting can handle depends on the machine’s power.

Handheld plasma cutters typically cut steel up to 38 mm thick.

More advanced CNC plasma cutting machines can manage materials up to 150 mm thick.

Other Conductive Metals

In addition to the metals mentioned above, plasma cutting can also be used on alloys and specialty metals, provided they are electrically conductive.

This flexibility makes plasma cutting a valuable tool in a wide range of industries.

What are the Advantages to Plasma Cutting?

Plasma cutting offers several benefits:

Speed and Efficiency

Plasma cutting offers much faster cutting speeds compared to traditional methods such as oxy-fuel cutting or sawing.

This is particularly noticeable on thin to medium-thickness metals, where plasma cutting can complete jobs in a fraction of the time.

The increased speed translates into higher productivity and lower labour costs.

Precision and Clean Cuts

The plasma arc produces a narrow kerf, allowing for highly precise cuts with minimal material waste.

The edges are usually smooth and require little to no secondary finishing, reducing the need for grinding or sanding.

This level of accuracy is especially valuable in industries where precision is critical, such as aerospace and automotive manufacturing.

Versatility

One of the greatest advantages of plasma cutting is its ability to cut a wide variety of electrically conductive metals.

It works efficiently on mild steel, stainless steel, aluminium, brass, copper, and many alloys.

Plasma cutters can also handle metals of varying thicknesses, making them suitable for everything from light fabrication work to heavy industrial tasks.

Cost-Effective Operation

Plasma cutters have lower operational costs compared to some other cutting technologies.

They do not require expensive gases or complicated set-ups, and the consumable parts last a reasonable time with proper use.

The reduced preparation and finishing work also contribute to overall cost savings.

Ease of Use

Modern plasma cutting equipment is designed to be user-friendly.

Many models include digital controls, safety features, and intuitive interfaces, which allow operators to learn and operate the machines with minimal training.

Handheld plasma cutters are especially valued for their portability and convenience.

Safety

Unlike cutting torches that use flammable gases, plasma cutting uses compressed air or inert gases, which makes it inherently safer.

However, standard safety equipment, including protective clothing and ventilation, are still essential.

What are the Disadvantages to Plasma Cutting?

Despite its advantages, plasma cutting has some limitations:

Limited to Conductive Materials

Plasma cutting is only effective on electrically conductive metals such as steel, aluminium, copper, and brass.

It cannot be used on non-conductive materials like wood, glass, or plastics.

This limits its use in certain industries and applications.

Thickness Constraints

While plasma cutting excels at cutting thin to medium-thickness metals, it is less suitable for extremely thick materials.

Oxy-fuel cutting remains the preferred method for very thick steel sections.

Attempting to cut beyond the machine’s capacity can result in poor-quality cuts and excessive wear on the equipment.

Surface Finish May Require Post-Processing

Although plasma cutting produces smooth edges, in some cases, particularly with thicker materials, there may be a slight amount of dross (melted metal residue) left on the cut edge.

This requires additional grinding or finishing to achieve a clean surface, which adds time and effort to the process.

Noise and Fumes

Plasma cutting generates significant noise, intense heat, and harmful fumes.

Proper ventilation and fume extraction systems are necessary to protect operators from inhaling toxic gases and particles.

Additionally, the noise levels can be damaging without suitable ear protection.

Energy Consumption

Plasma cutting systems require substantial amounts of electrical energy to operate, especially when cutting thick or large sheets of metal.

This can lead to higher electricity costs compared to some traditional methods.

Initial Equipment Costs

Although operational costs are relatively low, the upfront cost of purchasing a high-quality plasma cutter can be significant.

Additional costs may include consumables such as electrodes and nozzles, which require periodic replacement.

Who Sells Plasma Cutting Machines?

Several well-known manufacturers and suppliers offer high-quality plasma cutting machines for a range of applications.

Xtreme Plasma

Xtreme Plasma specialises in CNC plasma tables and related equipment.

Their machines are designed for high precision and efficiency, making them suitable for both small workshops and large industrial operations.

Xtreme Plasma also provides custom solutions, helping businesses meet specific cutting needs.

Parweld

Parweld is a trusted name in welding and cutting equipment.

They offer a selection of plasma cutting machines designed for ease of use and durability.

Parweld plasma cutters are known for their reliability and are widely used across industries such as fabrication, automotive repair, and construction.

GYS

GYS provides a broad range of plasma cutters, catering to professionals and occasional users alike.

Their machines offer advanced technology with user-friendly controls, making them suitable for a variety of cutting tasks.

GYS products are valued for their high performance, safety features, and energy efficiency.

Hypertherm

Hypertherm is recognised worldwide as a leader in plasma cutting technology.

Their machines are known for delivering excellent cutting quality, reliability, and long service life.

Hypertherm offers a wide range of products, from portable handheld plasma cutters to advanced automated systems.

Their equipment is widely used in demanding industries such as shipbuilding, manufacturing, and heavy equipment repair.

Conclusion

You should now have an understanding of exactly what is plasma cutting.

Plasma cutting is a powerful and efficient method for cutting electrically conductive metals, offering a unique combination of speed, precision, and flexibility.

It has earned a well-established place across a wide range of industries, including automotive repair, construction, metal fabrication, and shipbuilding.

Whether for heavy industrial work or smaller, detailed projects, plasma cutters provide a solution that is both reliable and cost-effective.

However, as with any technology, understanding the process is essential to achieve the best results.

Knowing the strengths and limitations of plasma cutting helps users select the right equipment, apply the correct techniques, and ensure safety during operation.

As industries continue to evolve and demand greater accuracy and productivity, plasma cutting stands out as a dependable method that adapts to new challenges.

By learning how to incorporate plasma cutting effectively, users can enhance their fabrication capabilities and achieve superior results across a wide range of projects.

For more information on plasma cutting, or help with your plasma table needs, get in contact here with us at Xtreme Plasma.

Powered by Lightspeed

Display prices in:GBP