Trade Counter Open Monday to Friday, 8.30am-5pm

4x2 CNC Plasma Cutting Table Kit

SKU 4x2complete

Plasma Cutter & Compressor Sold Separately , 3 Year Warranty

Table Layout

Water Tray & Brackets 4x2

£4,929.99

£4929.99 +Vat

In stock: 1 available

1

Save this product for later

4x2 CNC Plasma Cutting Table Kit

Product Details

Weight: 200.00 kg

4x2 CNC Plasma Cutting Table Kit – Powerful Performance in a Compact Footprint

For makers, fabricators, and small manufacturers looking to bring professional-level cutting to their workshop, the 4x2 CNC plasma table from Xtreme Plasma is what you need.

Proudly built in the UK, this entry-level CNC plasma cutting system brings accurate, high-quality metal cutting to light industrial users, hobbyists, and creative designers alike.

Whether you’re producing custom signs, metal art, or small-scale fabrication parts, this table is designed to give you the performance and precision needed without the high price tag of larger industrial machines.

CNC plasma cutting is no longer just for big factories, it's now fully accessible thanks to smart, space-efficient solutions like this one.

Made in the UK, Built for Real-World Workshops

Manufactured by Xtreme Plasma, this cnc plasma table has been purpose-built for UK workshops and garages.

Designed with a 1250mm x 625mm cutting area (4’ x 2’ sheet size), it can be used in both landscape and portrait configurations to suit different material sizes.

The landscape mode offers a 1250mm x 425mm area, while the portrait orientation provides 550mm x 1100mm, ideal for fitting longer shapes or nested designs.

Accuracy is rated at +/-1mm, giving you excellent detail and repeatability across cuts.

This is a serious piece of equipment made by engineers, for engineers.

Every part of the system has been selected to deliver real value, performance, and reliability in everyday use.

A Complete CNC Cutting Package

What makes this cnc plasma table kit stand out is its completeness.

You don’t just get a cutting table, you receive the entire system required to get started, minus the plasma cutter and air compressor.

The kit includes the bolt-together steel table, a black computer desk, a 22” LED display screen, a Windows-based PC system, a UK-built CNC controller, and all the electronics you need.

The bolt-together frame is strong and rigid, designed for easy transport and assembly.

All parts arrive part-assembled with step-by-step instructions, making setup simple even for first-time users.

You’ll also benefit from free technical support during normal working hours and a 3-year warranty on the table electronics.

Advanced Torch Height Control for Cleaner Cuts

One of the most important components of any cnc plasma table is the torch height controller (THC).

The THC automatically adjusts the height of the plasma torch during cutting, maintaining an optimal distance from the material surface.

This leads to better cut quality, longer consumable life, and more consistent results.

The torch height control is fully integrated into the software and controller, providing seamless operation.

Whether you're cutting 1mm sheet or 10mm plate, the THC ensures every cut is as clean and efficient as possible.

Powerful Software with Intuitive Interface

Included in the kit is a complete software package tailored to users of all skill levels.

You can draw parts in your preferred CAD system and import DXF files directly into the cnc plasma table.

Scaling artwork to fit available sheet sizes is straightforward, and the intuitive graphical interface helps users prepare files quickly and accurately.

The software suite includes over 50 tuition videos, manuals, and documentation to help you get started.

It also comes with a nesting tool, an HVAC duct creator with 14 preloaded shapes, and a comprehensive shape library.

This makes it especially useful for ducting professionals, general fabricators, and designers creating repeatable parts.

High-Performance Mechanics and Motion Control

Performance is at the heart of this cnc plasma table.

It features high-quality 3.1 Nm NEMA stepper motors and a rack-and-pinion drive system capable of speeds up to 10 metres per minute.

The XYZ gantry is smooth and accurate, enabling rapid movement without sacrificing quality.

The entire system is powered via standard 240V 13A single-phase electricity, making it a plug-and-play option for most garages and small workshops.

No three-phase power is required, and it’s compatible with many popular plasma cutters, including the R-Tech P51D plasma cutter.

Replaceable Slats and User-Friendly Maintenance

The cnc plasma table comes equipped with dual-sided replaceable slats.

This feature ensures you can maintain a clean cutting surface and extend the life of the bed.

As slats wear out, they can be flipped or swapped out without hassle.

This helps keep your machine running at peak efficiency and reduces downtime between jobs.

Built for practical use, the system is easy to clean, maintain, and service, even for users with minimal CNC experience.

Everything is designed to minimise effort and maximise time spent cutting.

Technical Support and Long-Term Value

When you invest in a cnc plasma table, ongoing support is crucial.

Xtreme Plasma provides UK-based customer support and is available during regular working hours to assist with setup, troubleshooting, or usage questions.

The electronics are backed by a 3-year warranty..

This peace of mind makes the 4x2 CNC plasma table kit a smart long-term investment for anyone serious about growing their workshop’s capabilities.

Affordable CNC Cutting Without Compromise

The 4x2 CNC plasma table kit from Xtreme Precision Engineering proves that high-quality plasma cutting doesn’t have to come with a high price tag.

With professional features like automatic torch height control, advanced motion systems, intuitive software, and a UK-built control system, this machine delivers exceptional results in a compact footprint.

Perfect for light manufacturing, artistic metalwork, HVAC fabrication, and DIY enthusiasts, this cnc plasma table is an ideal starting point, or upgrade, for anyone looking to bring precision metal cutting into their own workspace.

For more information on plasma cutters, or help with any and all of your plasma cutting needs, get in contact with us here at Xtreme Plasma.

We also sell different size plasma tables including:

You May Also Like

CNC Ready

R-Tech P51D Digital CNC Plasma Cutter (240v) ipt-60 Hand & upm105 Machine Torch

R-Tech P51D Digital CNC Plasma Cutter (240v) ipt-60 Hand & upm105 Machine Torch

Single Phase 240v 32amp Pierce up to 12mm steel* £1270.00 +vat

£1,365.00

£724.00 +Vat

ABAC Extensive EXT A39B 200 CM3 UK Belt Drive Compressor

ABAC Extensive EXT A39B 200 CM3 UK Belt Drive Compressor

200Litre Tank Stationary compressor 240v 16amp Suitable for the P51D/45CT

£724.00

CNC Ready

R-Tech 100amp P101D CNC Plasma Cutter & Machine Torch

R-Tech 100amp P101D CNC Plasma Cutter & Machine Torch

100amp 3 Phase 415v PIERCE UP TO 20MM STEEL*

£2,191.00

£1033.00 +Vat

Abac PRO B5900B 200 FT5.5

Abac PRO B5900B 200 FT5.5

200Litre Tank Stationary compressor 400v 16Amp Suitable for the P100cnc

£1,033.00

£68.50 +Vat

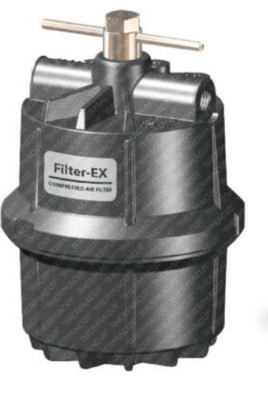

FILTER-EX AIR (AT1000 Compressed Air Filter)

FILTER-EX AIR (AT1000 Compressed Air Filter)

Recommended For Plasma

£68.50

CNC Plasma Cutting Table - Configured to your specification

CNC Plasma Cutting Table - Configured to your specification

quality, reliability, and user-friendliness . 3 Year Warranty, From £4929.99 +Vat

£5,229.99

SheetCam License

SheetCam License

CAM,Basic Nesting,Shapes Library, Arcdroid and Myplasm compatible

£96.67

Display prices in:GBP