Trade Counter Open Monday to Friday, 8.30am-5pm

Plasma Cutters, Plasma Tables & Consumables

Plasma Cutters - Unleash the Power of Precision

The Speed and Efficiency of Plasma Cutters

Plasma cutters are known for their impressive speed and performance.

They use a high-temperature plasma arc to cut through metal quickly and accurately.

Compared to traditional methods like oxy-fuel cutting, plasma cutters provide faster results with less effort.

This helps businesses and workshops complete projects in less time.

The increase in cutting speed improves productivity and can reduce overall project costs.

Whether you’re working with thin sheet metal or thicker materials, a plasma cutter delivers clean and fast results every time.

Plasma Cutters Bring Versatility to Metal Cutting

One of the key benefits of plasma cutters is their versatility, be it in a plasma cutter machine or a cnc plasma table.

They can cut a wide range of metals including mild steel, stainless steel, aluminium, brass, and copper.

This makes them suitable for many industries, from automotive and construction to metal fabrication and repair work.

Plasma cutters can handle different material thicknesses, giving users the flexibility to tackle various tasks with one tool.

Whether you’re shaping custom parts or cutting large sheets, a plasma cutter offers the precision and adaptability you need.

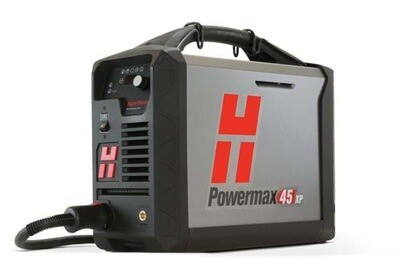

Portable and Easy to Use

Plasma cutters come in various sizes, from small handheld units to large industrial machines.

Handheld cutters are ideal for small jobs or site work where mobility is important.

Larger units are designed for heavy-duty use and can cut through thick metals with ease.

Many modern plasma cutters feature simple controls, allowing users to adjust settings like amperage and airflow quickly.

Even beginners can achieve great results with minimal training, making these tools perfect for both professionals and DIY users.

Cost-Effective Metal Cutting

Using plasma cutters can also help reduce costs.

They produce minimal waste, meaning less material is lost during cutting.

The clean cuts they create require little to no finishing work, saving time on grinding or sanding.

In production settings, the speed and efficiency of plasma cutting can significantly reduce labour and energy costs.

Overall, plasma cutters offer a reliable, affordable, and high-performing solution for any metal cutting task.

Some of the Best Plasma Cutters

When choosing the right plasma cutter, it's important to consider power, reliability, and ease of use.

Below are some of the best plasma cutters available today, each offering excellent performance across a range of applications.

R-Tech P50 CNC Plasma Cutter

The R-Tech P50 CNC is designed for precision and reliability, especially when paired with a CNC plasma table.

It offers consistent cuts up to 12mm and clean results up to 16mm.

It's a solid choice for workshops needing CNC compatibility.

GYS 70 CT Plasma Cutter

Known for its power and portability, the GYS 70 CT delivers strong cutting performance on materials up to 30mm thick.

It's ideal for industrial use and heavy-duty tasks.

Thermacut Ex-Trafire 125HD

The Thermacut Ex-Trafire 125HD is built for high-demand environments, this heavy-duty cutter features 125A cutting power and is suitable for thick metal plate applications.

It's a top-tier choice for fabrication shops and manufacturers.

Parweld XTP 40 Dual Voltage Plasma Cutter

The Parweld XTP 40 is compact and versatile, this 40A plasma cutter operates on both 110V and 230V, making it perfect for site work and smaller workshops.

It cuts cleanly through up to 12mm of metal.

An Essential Tool for Today’s Metalwork

Plasma cutters have changed the way metal is cut, offering a combination of speed, accuracy, and flexibility.

From hobbyists to industrial users, they are a valuable tool in any workshop.

For more information on plasma cutters, or help with your plasma cutting needs, get in contact with the team here at Xtreme Plasma today.

Refine by

CNC Ready

R-Tech P51D Digital CNC Plasma Cutter (240v) ipt-60 Hand & upm105 Machine Torch

R-Tech P51D Digital CNC Plasma Cutter (240v) ipt-60 Hand & upm105 Machine Torch

Single Phase 240v 32amp Pierce up to 12mm steel* £1270.00 +vat

£1,365.00

Hand Cutting

R-Tech P101D CNC Plasma Cutter (415v) ipt-100 Hand Torch

R-Tech P101D CNC Plasma Cutter (415v) ipt-100 Hand Torch

100amp, 3 Phase 415v Cut upto 40mm Steel

£1,749.00

CNC Ready

R-Tech 100amp P101D CNC Plasma Cutter & Machine Torch

R-Tech 100amp P101D CNC Plasma Cutter & Machine Torch

100amp 3 Phase 415v PIERCE UP TO 20MM STEEL*

£2,191.00

£1258.45+Vat

GYS 45CT with TPT40 Hand Torch

GYS 45CT with TPT40 Hand Torch

was £1,607.00

Save £348.55

£1,258.45

£902.70 +Vat

GYS PLASMA CUTTER K25 - TORCH INCLUDED

GYS PLASMA CUTTER K25 - TORCH INCLUDED

Built in Compressor

£902.70

New Model

GYS EASYCUT K35 PFC

GYS EASYCUT K35 PFC

Built in Compressor £1164.96+vat

was £1,618.00

Save £453.04

£1,164.96

£1822.45 +Vat

GYS CNC PLASMA CUTTER 45CT & Machine Torch

GYS CNC PLASMA CUTTER 45CT & Machine Torch

CNC Ready 45Amps Cutting Power 240volts

£1,822.45

£2627.10 +Vat

GYS PLASMA CUTTER 70CT & Machine Torch

GYS PLASMA CUTTER 70CT & Machine Torch

CNC Ready 70Amps Cutting Power 415volts

£2,627.10

£4127.60 +Vat

GYS Plasma Cutter Neocut 125 - Without Torch

GYS Plasma Cutter Neocut 125 - Without Torch

125 Amps Cutting Power 415volt (This Model is being Discontinued)

£4,127.60

NEW

Cobra by Stealth Cut 45 PFC LCD Plasma Cutting Machine

Cobra by Stealth Cut 45 PFC LCD Plasma Cutting Machine

£750 +vat Suitable for Arcdroid

£750.00

Display prices in:GBP